Improve the precision of your sample delivery

Automate your entire biomedical analysis process

Maintain accurate and auditable environmental controls

Saguaro is applying our vast expertise in automated material handling — operation flow control, equipment monitoring, data collection and analysis, and complete process automation solutions — to streamline software and firmware development and make various life sciences industry processes more efficient and accurate.

Examples of Saguaro life science client work include:

We offer test validation of various laboratory systems and comply with life science industry standards such as:

If you’re finding it difficult to secure the software engineering talent you need to stay competitive, you’re not alone.

As our clients over the past quarter century have found, Saguaro can help. By tapping into our deep technical resources, you can scale your programs more quickly, easily, and effectively.

Our expertise extends across programming languages, web technologies, operating systems, databases, tools, and more — everything needed to automate and control sophisticated life sciences test and delivery systems.

Carefully matching our talent pool with your specific needs, we can tackle even your most complex, business-critical lab automation projects.

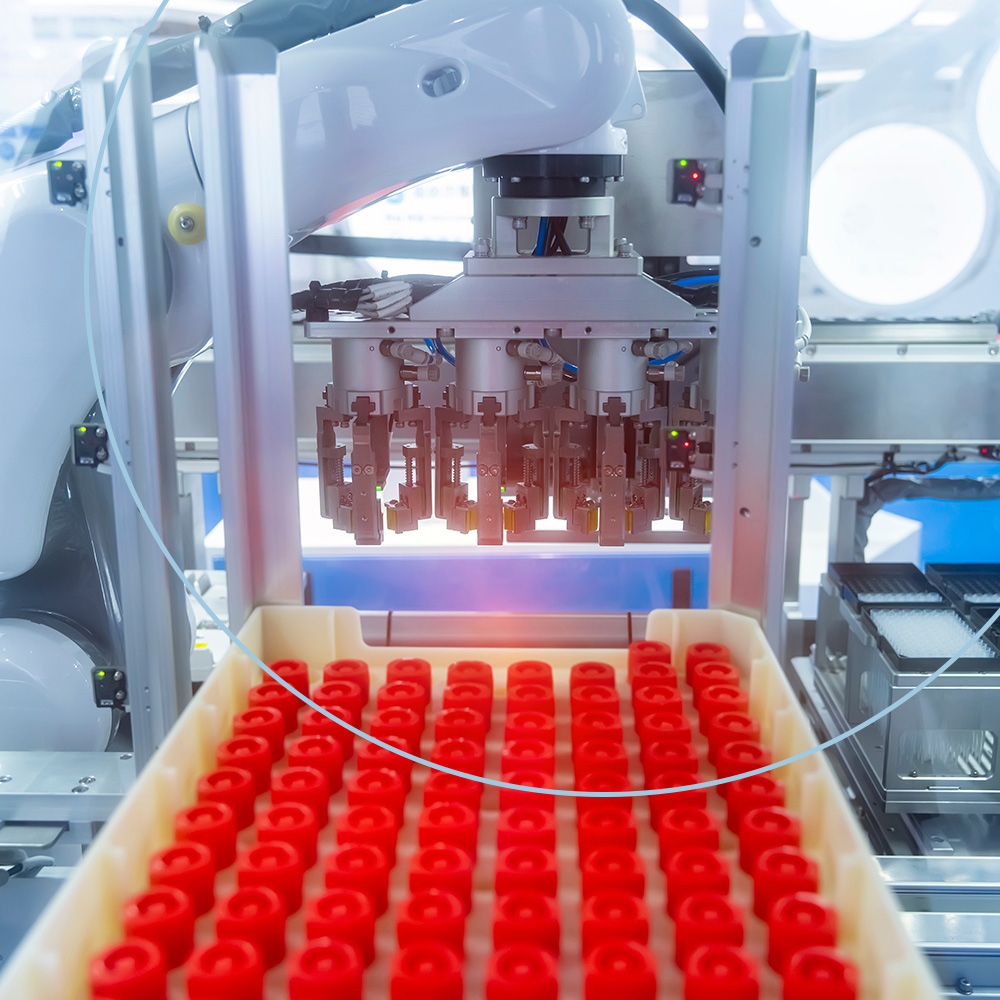

Challenge: A major laboratory client of a leading provider of life sciences solutions worldwide needed to deliver large numbers of required sample tubes at precise times.

Solution: Saguaro used machine learning technology to implement a task predicter that determined precisely how much time the tube delivery would take.

Result: The life sciences company can now accurately estimate the time required to extract a specific number of specific tubes from its biostore.

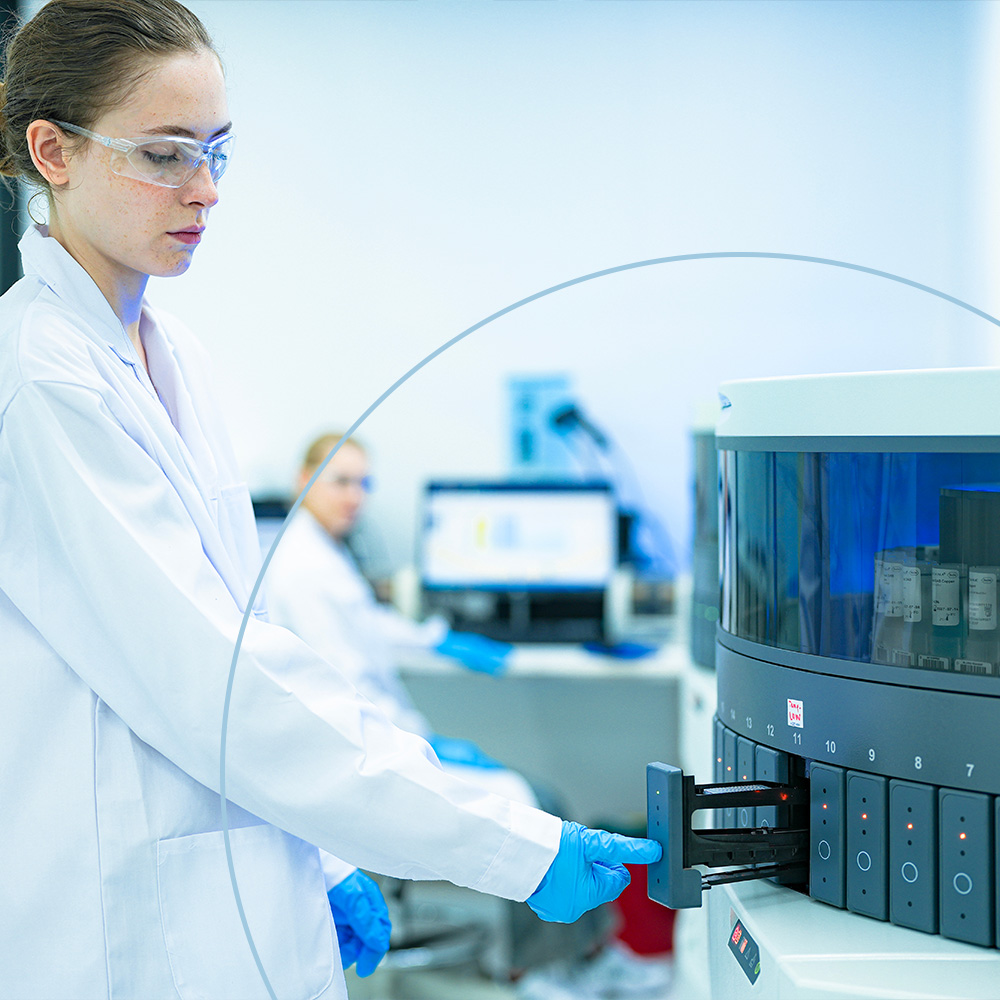

Challenge: A leading manufacturer of ELISA systems needed a reliable and automated way to integrate ELISA medical instruments with its laboratory information system (LIS).

Solution: Saguaro developed and implemented a custom solution that acts as a bridge between the ELISA instruments and the LIS. We handled the full integration stack, from the communications layer (TCP/IP or serial) to protocol handling (LIS01/02 and HL7), message parsing, result transformation, and error management.

Result: By seamlessly translating instrument output into HL7 or LSI02 messages, we ensured bi-directional communication of test orders and results, including detailed logging, monitoring, and error handling. As a result, the manufacturer’s lab staff can now focus on analysis instead of data management, while achieving improved compliance with healthcare data standards.

The Saguaro Life Sciences lab is equipped with instruments that fully automate 2-plate and multi-plate ELISA systems for Dynex Technology, able to handle multiple assays on 96-well plates in a single run. We use these instruments to test, validate, and optimize the software that controls sample processing, incubation, washing, and detection, ensuring our automation software performs accurately across multiple assays and plate formats.

This lab also has equipment to support our development with Azenta, including printers and barcode scanners that use a variety of methods for inventory management. We use these tools to simulate real-world sample management and storage scenarios — testing, validating, and optimizing software that handles tube marking, barcode scanning, data capture, and inventory tracking within automated sample stores and cryo stores.